Sustainability is important in Kulinaaria – we take into account the goals of sustainable development in our production, products, packaging and employee well-being, as well as in the supply chain.

In addition to our efforts to date, we are renewing our sustainability strategy to adopt even more ambitious climate goals and to focus on where we can have the greatest impact.

Ecological environment

We value the environment around us and support solutions that help reduce our climate impact.

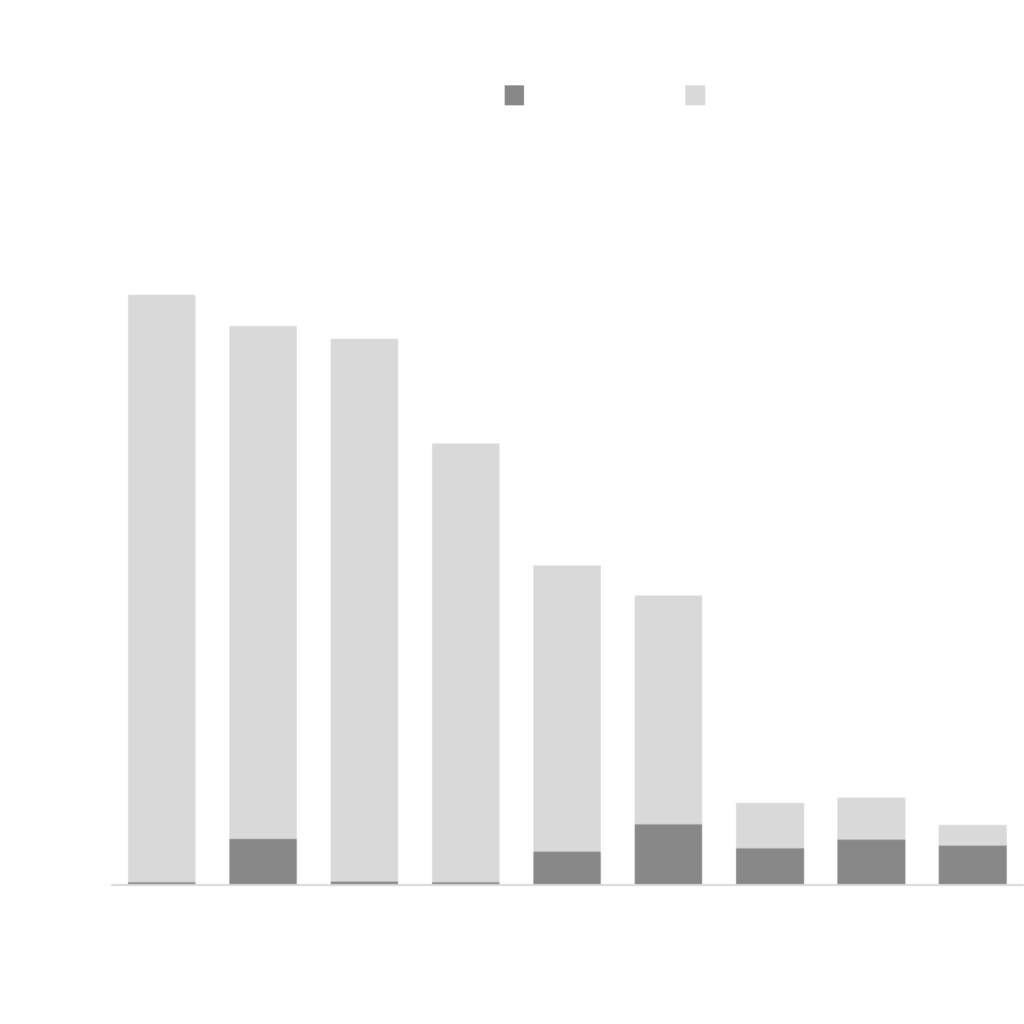

CO2 footprint 2016-2024 (absolute emissions)

Kulinaaria’s emissions were measured according to the GHG Protocol. Scoop 3 (waste) was measured for the first time for 2022. Our footprint has shrunk about 80% in 6 years thanks to environmentally friendly solutions and more resource-efficient production. In 2022, the footprint was significantly reduced due to the use of green electricity, which we introduced in the second half of 2021. In 2023, the footprint increased slightly due to a refrigerant leak.

| 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

| Scope 1 | 23 | 322 | 24 | 20 | 232 | 421 | 255 | 315 | 273 |

| Scope 2 | 4055 | 3540 | 3751 | 3032 | 1979 | 1582 | 315 | 291 | 142 |

| Scope 3 | 139 | 123 | 119 | ||||||

| Total | 4078 | 3862 | 3775 | 3052 | 2210 | 2003 | 709 | 729 | 534 |

Intensity (t CO2ekv/m²)

The intensity of Kulinaaria’s footprint has decreased ca 90% per area.

| 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

| t co2ekv/m2* | 0,97 | 0,92 | 0,9 | 0,72 | 0,28 | 0,25 | 0,09 | 0,09 | 0,07 |

| Area m2 | 4214 | 4214 | 4214 | 4214 | 7902 | 7902 | 7902 | 7902 | 7902 |

* Carbon footprint per area

Electricity and heating

In September 2021, we switched to 100% green electricity. In addition to the use of electricity produced from renewable sources, it is important to reduce electricity consumption.

To achieve energy savings, we have installed LED lights. We also use various smart building principles, such as regulating the lighting according to daylight and movement, adjusting the ventilation as needed, and window sensors that regulate heating/cooling when opening windows.

In 2020-2021, we expanded our factory by 50% to 8 000 square metres, and we also renovated the original plant. Following the completion of the renovation, we will use CO₂-based refrigeration equipment in our production, which has a footprint almost 4 000 times smaller than that of equipment running on freons.

We also use the residual heat from cold production to heat domestic water and to reduce thermal energy consumption. In addition to expanding the plant, we also built a steam boiler plant that uses natural gas as fuel and thus reduces electricity consumption. In production, we can use steam to heat boilers faster and thus ensure a more efficient work process.

Materials

When choosing packaging, we choose materials that can be or are already recycled.

At the end of 2021, for example, we introduced salad trays made from 100% recycled material, which means that we use 50 tons less primary production plastic per year. In addition, the new tray is thinner and we use 3,6 tons less plastic for the same packaging per year.

Waste

We sort metal, glass, cardboard, film and food waste generated in our production separately to increase waste recycling.

When it comes to purchasing raw materials, we also consider the way they are packaged in order to avoid excessive packaging waste.

Production and product development

Kulinaaria has an ISO 22000:2018 food safety certificate. We have strict product safety requirements, and we conduct regular quality inspections to ensure them.

Production

Along with expanding production, we have also upgraded our equipment to ensure greater automation and productivity, and thus more resource-efficient production.

In addition, the new equipment can ensure a longer shelf life, which helps reduce food waste.

With the updating of the production equipment, we were also able to expand our portfolio – we have introduced soups and tube-packaged doughs as innovative solutions.

Logistics

We have developed the capacity to adopt a standardised and environmentally-friendly transport packaging system.

Our boxes are made of 100% recyclable materials, and broken boxes are granulated and used to make new boxes. Standardised boxes help prevent products from breaking and allow them to be compactly packed and transported, reducing food waste and fuel consumption. Logistics processes are paperless, making administration fast and convenient.

We are open to new solutions – we are participating in a pilot project where we are testing robots to optimise logistics in cooperation with Tallinn University of Technology. Robots can be used to transport raw materials, packaging and products from one production plant to another, which makes production logistics more efficient and reduces the burden on transport workers.

Healthy food

Whole and healthy food is important to us. To improve our overall offering, we work with TFTAK, the Center of Food and Fermentation Technologies, to bring products with health-promoting components to market.

The selection includes broccoli purée soup enriched with beneficial nutrients and vitamins, sauerkraut soup, pumpkin purée soup, and tomato and fish soup. Due to using hot dispensing and packaging, no preservatives have been added to the soups.

Investing in people and the community

We value our employees and consider ourselves part of the community. It is important for us to ensure the safety of our workplace and to act in an honest and ethical way, and we follow the principles of good business practice in our operations.

Our people

We ensure a safe working environment for our employees to prevent workplace accidents.

To this end, we provide comprehensive on-the-job training for new employees, and there are also senior staff in each department to help new people settle in.

Every year, we offer employees the opportunity to be vaccinated against the flu at work. In order to promote a healthy lifestyle, we offer our employees incentives to engage in sports opportunities. In addition, we recognise long-term employees by granting them additional days off and a bonus every year. We also organise events within the company.

Community

In the second half of 2021, we started cooperating with the Food Bank and donated more than 1.3 tons of food in a short amount of time. The cooperation will continue this year as well, and we hope to reach even more people in need.

We offer internships for people with special needs to enable them to apply what they have learned in the courses and thus enter working life more successfully.